ARTWORK/PREPRESS

Bitmap – An image made up of dots or bits of information. Bitmaps and jpegs will lose resolution when enlarged and gain resolution when reduced, proportional to the amount of change in the size of the image.

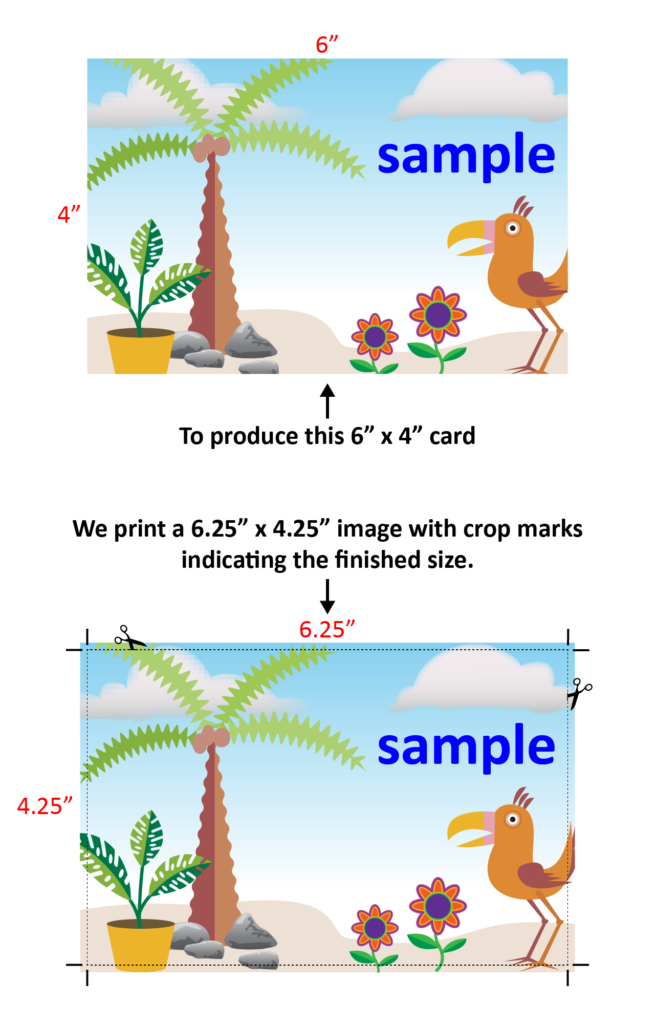

Bleed or bleeds – An image or art element is said to bleed when it extends to the edge of the finished printed piece. A printed piece is said to have bleeds when it contains images or art elements which extend to the edge of the finished printed piece. Since most printing devices cannot print all the way to the edge of the sheet, an OVERSIZE IMAGE is printed on an oversize sheet and then trimmed to the finished size. Care must be taken in placing the artwork elements on the oversize image so they will be in the proper position when the extra IMAGE bleed area is trimmed off. For example, a 6 x 4 postcard which bleeds is printed as a 6.25 x 4.25 image and then 1/8″ (.0125″) is trimmed off every edge, yielding the 6 x 4 finished card with bleeds.

Camera ready – Physical original ready to be scanned for printing.

Gripper – The strip along one edge of the sheet which cannot be printed because it is reserved for the press to grip (hold) it, while passing it through the press.

Pagination – Arranging pages of a book in the correct order for printing in order to render the desired page order when the job is printed, collated, bound and trimmed.

Print ready – Electronic file ready to be sent directly to a digital printing device.

Resolution – Measured in dpi (dots per inch), resolution is the gauge of the amount of detail in bitmap or jpeg image.

Vector Image – An image made up of vectors or instructions on how an image should display or print. Vector images can be enlarged without loss of resolution.

Void Area – The area on the margins of a sheet which cannot be printed by a laser printer/copier, usually 1/8” to 3/16”.

PAPER

Carbonless Paper – Paper coated in such a way that when written upon, the image transfers to the sheet(s) below, without the use of carbon paper.

Coated Paper – Paper coated with a clay or other coating, which yields more pure colors and sharper images than uncoated papers. Coated papers may be cast coated (almost wet gloss), matte coated (non-glossy) or glossy.

Finishes available on coated paper

Matte Coated – Clay coated paper with no “glossing” process applied to the paper.

Gloss Coated – Clay coated paper which is passed over spinning rollers which calender the finish to a gloss

Cast Coated – Paper coated with a liquid which when dried yields a wet, glossy appearance.

Uncoated Paper – Paper which is not coated, it is less expensive and weighs less than coated papers.

Finishes available on uncoated paper

Smooth – just what it sounds like.

Super Smooth – Additional pressure during manufacture yields a smoother surface than smooth.

Laid – Rough parallel lines

Linen – Fine crosshatch, like linen.

Vellum – Semi-rough finish, not to be confused with the translucent paper known as vellum.

PRINTING

Blind Embossing – Using a die, an image is impressed in the stock from the back. When impressed from the front, it is referred to as debossing.

Digital Printing – This term encompasses laser printing and inkjet printing, utilizing images electronically stored and transmitted to the printing device.

Foil Stamping – An image is transferred to a sheet of stock by pressing a metallic foil or plastic “foil” between a heated die and the stock.

Foil Embossing – The same image is foil stamped and embossed on a sheet.

Four color (process) printing – Printing by which a range of colors are printed in one pass through the varying combination of dots of four (primary) colors: cyan, magenta, yellow and black.

Laser printing – Printing by electronically arranging an image with powder on a drum or belt, transferring the image to the paper, then fusing the image to the paper with a combination of heat and pressure. Generally, the toner powder can be black (for black & white printing) or four colors (cyan, magenta, yellow, and black), which allows a range of colors to be printed in one pass.

Letterpress – Printing method by which physical raised type is inked and then pressed against the paper.

Offset Printing – Rotary printing method by which an image on a thin metal, plastic or paper plate is inked, then transferred to a rubber “blanket”, then transferred to the paper by squeezing the paper between the “blanket” and an impression cylinder.

Spot Color – In offset printing, mixing the desired color ink and printing it in specific places (spots) on the paper, in contrast to four color process printing, in which a whole range of colors can be printed in one pass. Spot colors are more pure than their four color process equivalents.

Thermography – Originally developed as an inexpensive alternative to engraving (printing from a depressed surface), thermography produces a raised image composed of ink and a powdered rosin. The image is first printed by offset or letterpress, then dusted with a rosin powder, which sticks to the still-wet ink. The excess rosin is then vacuumed off the sheet and the rosin and ink are combined by exposing the printed sheet to high heat.

BINDERY

Folding – Thin papers can be folded without prior preparation. Thick papers or gloss papers should be scored before folding to help control the placement of the fold and minimize cracking/wrinkling when folding.

GBC® – Slotted holes punched along the edge of a book, bound by a spine with fingers which curl through the slots back to the spine. GBC® bound books lay flat when open and the pages are aligned. Pages can be added and subtracted to finished GBC® bound books without replacing the spines (provided a different size spine is not required).

Numbering – Sequential numbering can be added during laser printing by merging numerical data with the art file or it can be added after printing (laser or offset) using a numbering machine. On multiple part carbonless forms, use of a numbering machine allows the number to transfer through to all copies.

Perforation – A series of small, short slits which allow a part of a sheet to be removed without cutting.

Plasticoil – Round holes punched along the edge of a book, bound by a plastic spiral which is crimped at each end. Plasticoil books lay flat when open but the pages are not aligned across the binding because of the spiral binding. Pages can be added and subtracted to plasticoil bound books, but the plasticoils have to be replaced when doing so.

Regular cover – Used for binding forms. Sheets or carbonless sets with a perforated stub are stapled on the stub with a tagboard cover on front and chipboard back. For carbonless forms, an additional thick piece of stock will have to be inserted behind the carbonless set being written upon to keep the image from transferring to the next set below. (See also Wrap Cover)

Saddle Stitch – Booklets are printed by printing two pages (four if both sides are counted) on one sheet, collating, folding, stapling through the fold and trimming the open right side (face).

Score – A straight-line indentation which allows a sheet to be folded, minimizing cracking and allowing more accurate placement of the fold.

Wrap cover – Used for binding forms. Sheets or carbonless sets with a perforated stub are stapled on the stub with a single piece of tagboard long enough to wrap from the stub on the front, over the top, down the back, around bottom and back up to the stub, allowing the cover to be used to separate the carbonless set in use from the sets below. A piece of chipboard is stapled on the back within the wrap cover to render the book more rigid. (See also Regular Cover)